Research Domains

Destructive and non-destructive examinations

To increase the products competitiveness, laboratory is equipped with advanced equipments that enable the research works, innovation and technology development:

Destructive tests

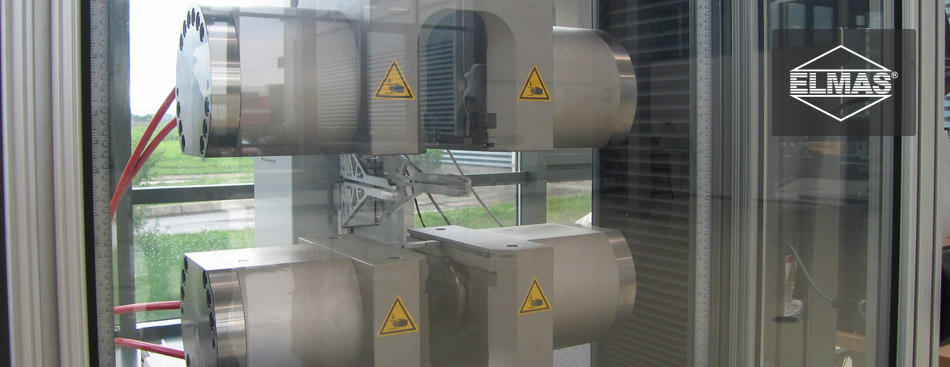

Tensile and compression tests with maximum force of 400 kN.

Resilience tests with standard methods (Charpy ISO, Charpy NIST E23) for metallic and welded joints, at ambient and low temperatures (-60° C/+100° C).

Sampling and cutting specimens of materials.

Microscopic analysis of materials and study of welded joints geometry.

Grinding and metallographic mounting resin of samples.

Analysis of chemical composition of materials.

Hardness measurements of metals (Brinell, Vickers or Rockwell).

Within Elmas testing laboratory the following type of non-destructive examinations authorized by ISCIR are performed:

Ultrasonic examination (UT)

Ultrasonic thickness measurements and ultrasonic examination by different methods: conventional, Phased Array and TOFD.

Dye penetrant examination (PT)

We provide dye penetrant examination (PT) for metallic or non-metallic materials.

Magnetic powder examination (MT)

We perform magnetic powder examination (MT) dry or in suspension for highligting open and closed discontinuities.

Visual examination (VT)

We are able to perform visual examination (VT) with experienced personnel in the field, to establish certain technical errors, surface states, surface discontinuities, etc.